In the digital age, production processes are constantly changing. As industries become increasingly connected, they innovate and gaps with the competition widen, ultimately leading to a loss of performance and profitability.

Working with you to define your objectives over the entire life cycle

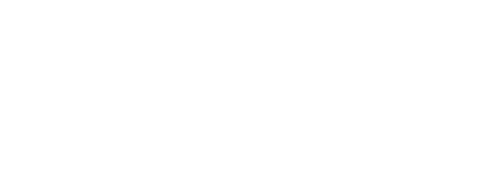

Whatever the industrial process in your activities is: Research & development, production, maintenance, logistics, infrastructure and utilities

Our innovation approach is aimed at all industries of the future; or rather, at each of them.

The purpose of these innovations is to:

- improve your energy performance

- anticipate and facilitate the maintenance of your equipment

- make you more competitive with a redesigned, agile, connected model that puts people at the centre and minimises resources

- reduce time spent on repetitive tasks

Optimize Research & Development

The Clemessy teams have deployed bespoke solutions that address your R&D challenges and are tailored to the needs of the market.

- Deliver R&D efficiency

- Reduce development, fine-tuning and burn-in cycle times

- Validate product endurance, performance or yield

Improve production

In response to a changing market, industrial companies must adapt to their customers’ new requirements: to be responsive to the market, and to customise and manufacture to order while promoting sustainable development and eco-responsibility.

To meet your production challenges, our teams support you throughout your production processes.

- Improve industrial performance

- Guarantee product quality, traceability and conformity

- Assist operators and ensure their safety

Transform industrial maintenance

Industrial maintenance is gradually being transformed in factories, with preventive maintenance now giving way to predictive solutions in the factory of the future.

Our teams offer you effective maintenance tools tailored to your equipment to help you address your challenges.

- Reduce the cost of maintenance

- Use resources only as and when needed

- Increase the availability and life span of production resources

- Anticipate and manage

Manage and secure infrastructure and utilities

To encourage an eco-responsible approach and address the need to secure infrastructures and utilities, the Clemessy teams can help you to:

- Optimise building management (agility and flexibility)

- Manage energy performance

- Reduce carbon footprint

- Protect industrial assets

Improve logistics efficiency

Streamlined logistics delivers a real competitive advantage. Optimal control of logistics allows for significant cost reductions while improving and automating transport and/or storage.

The Clemessy teams have developed solutions tailored to your logistics challenges.

- Geolocate products or containers

- Optimise stocks and storage space

- Streamline flows

- Enable digital customer/supplier exchanges

- Ensure traceability

Our technology components

Artificial intelligence • Augmented reality • Virtual reality • Cybersecurity • Industrial IOT • Big Data and data science • Cloud hosting • Industrial networks • Machine vision • Smart glasses • Image analysis • Data encryption • Web technologies • Mobility • Virtualisation • Deep learning • Machine learning • Industrial 5G • Blockchain

A collaborative approach

We offer you a 360° collaborative approach that incorporates three essential drivers for your performance:

- the integration of digital and information technology into each of our solutions

- an eco-responsible approach suited to low-carbon issues, taking consideration of people, their safety and well-being

- our ability to take action where you need it, from supplying a system to overall project management

Open Innovation

Our innovation model is based on a culture of sharing and collaboration. Our teams work with all the stakeholders in their ecosystem:

- startlab and incubator (KMØ)

- professional groups and associations (GIMELEC, CLUSIF, GIFEN, etc.)

- call for projects / expressions of interest

- competitiveness clusters

- partnerships with manufacturers and suppliers

- collaborations with research laboratories and universities

- apprenticeships and internships with schools and training organisations