We have the company and product certifications, which are essential for carrying out work on a site in operation. Thanks to our 800 authorised and qualified employees, we take action in close proximity and are also able to mobilize resources on complex projects by setting up a common technical platform close to our customers.

Expertise which meets the regulatory requirements of the nuclear industry

Clemessy has the certifications and qualifications that guarantee the level of our services. Our teams have an integrated management system which consolidates our commitments in terms of quality, safety, environment and nuclear safety. Improving the availability and reliability of the production plant, in compliance with safety and radiation protection regulations, is our daily priority.

Our teams have the UTO qualifications in the following fields:

- Electrical and monitoring & control work

- Boiler making

- Piping

- Instrumentation and tests

- Civil engineering

- HVAC engineering

- maintenance of valves and fittings

- rotating machinery

- and technical assistance.

Industries of the future

Discover how our experts can assist you in your transformation towards tomorrow’s evolutions.

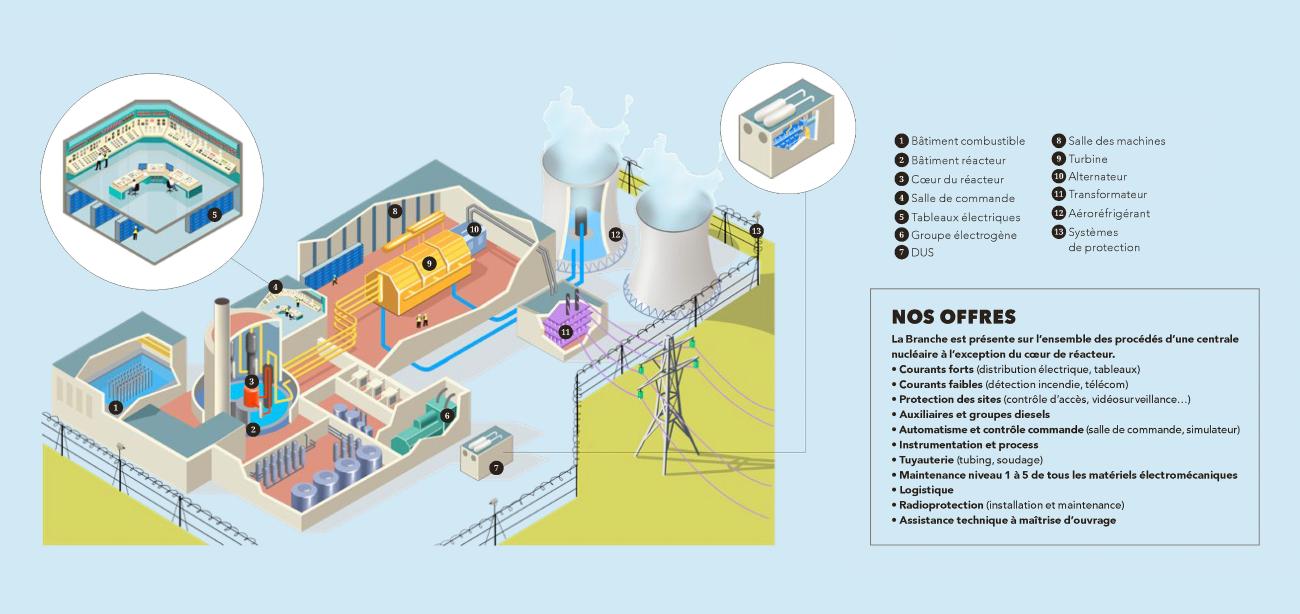

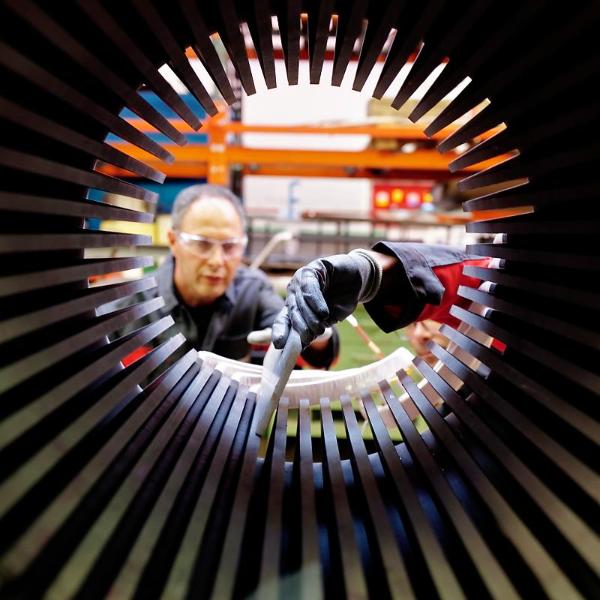

Proven expertise on the emergency back-up Diesel generator sets

As leader of a consortium of companies, Clemessy won the contract for the supply, installation and operational readiness of the emergency back-up diesel generator sets for all 900 and 1450 MW units for all the French nuclear power plants. In total, Clemessy is responsible for designing and implementing the electrical and monitoring and control systems of the auxiliary gen sets for 36 units.

Clemessy's teams are qualified to meet regulatory requirements to combat seismic risks and the ageing of equipment.

In addition to its traditional know-how, Clemessy offers:

- Site protection (access control systems, physical barriers, video-surveillance, centralized information, biometric control)

- Instrumentation and process (Analog/Digital regulation, physico-chemical measurements, process control)

- Piping (tubing, welding)

- Level 1 to 5 maintenance (preventive, curative and predictive, operational readiness, spare parts management)

- Logistics (management of equipment and services)

- Radiation protection (installation and maintenance).

SmartForest solution, data science at the service of industry, which allows :

- use big data and artificial intelligence

- determine the recurring usage patterns of the production unit

- identify the combination of factors influencing the performance of the machine

- be coupled, for example, with vibratory analyses and complex industrial processes: explanation of cycle time drifts in industrial installations

Digital technologies

- Connected glasses, augmented reality

- Virtual immersion in installations, such as a "Serious game

Predictive and prescriptive maintenance

Our complete offer

Discover our technical expertise

-

EDF - CNPE

EDF - CNPEThe Clemessy teams completed the DUS (emergency backup diesel generators on several French nuclear power plants.

-

-resize1200x750-crop750x750-resize600x600.jpg) EDF - CNPE

EDF - CNPEEDF awarded Clemessy a preventive and corrective maintenance contract for the Fessenheim power plant.

-

-resize1200x750-crop750x750-resize600x600.jpg) EDF - CNPE

EDF - CNPEThe Clemessy teams participated in the Grand Carénage project by carrying out work on the monitoring chains.

Consult all our job offers

Available to apprentices, to people looking for an internship or a job, and also to Eiffage employees, the Taléo search engine is the best way of finding out about openings available within the Group. “Area of employment”, “Location”, “Organisation”, “Fixed-term contract”, “Open-ended contract”, “Internship”, “Apprenticeship”: just fill in a few criteria to have real-time access to all the professional development opportunities.

-crop1200x1200-resize660x660.jpg)