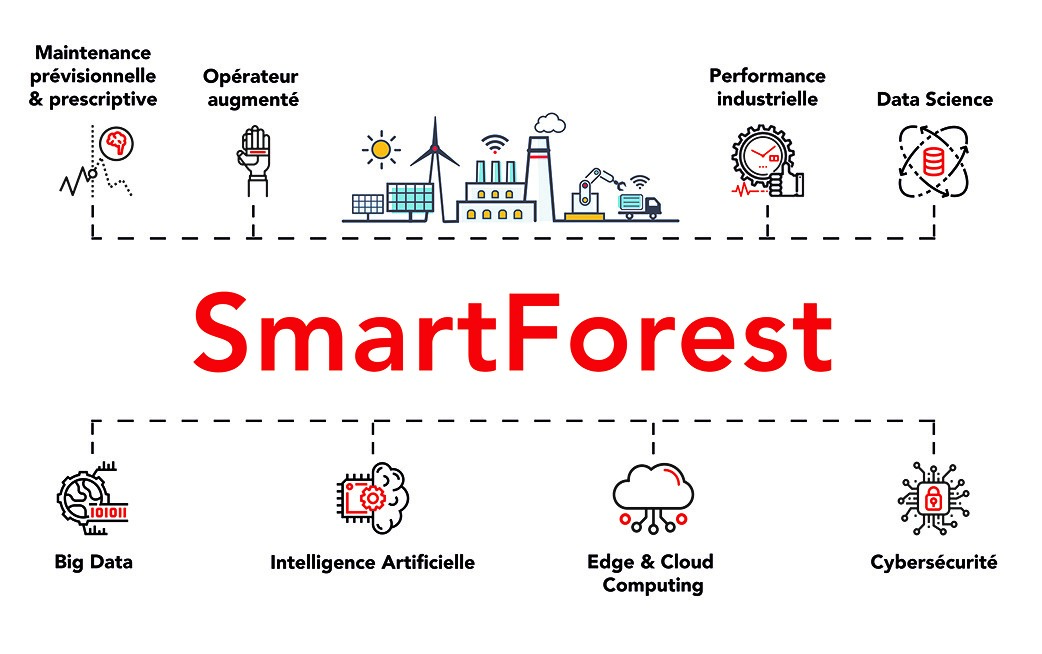

SmartForest: a global and flexible solution

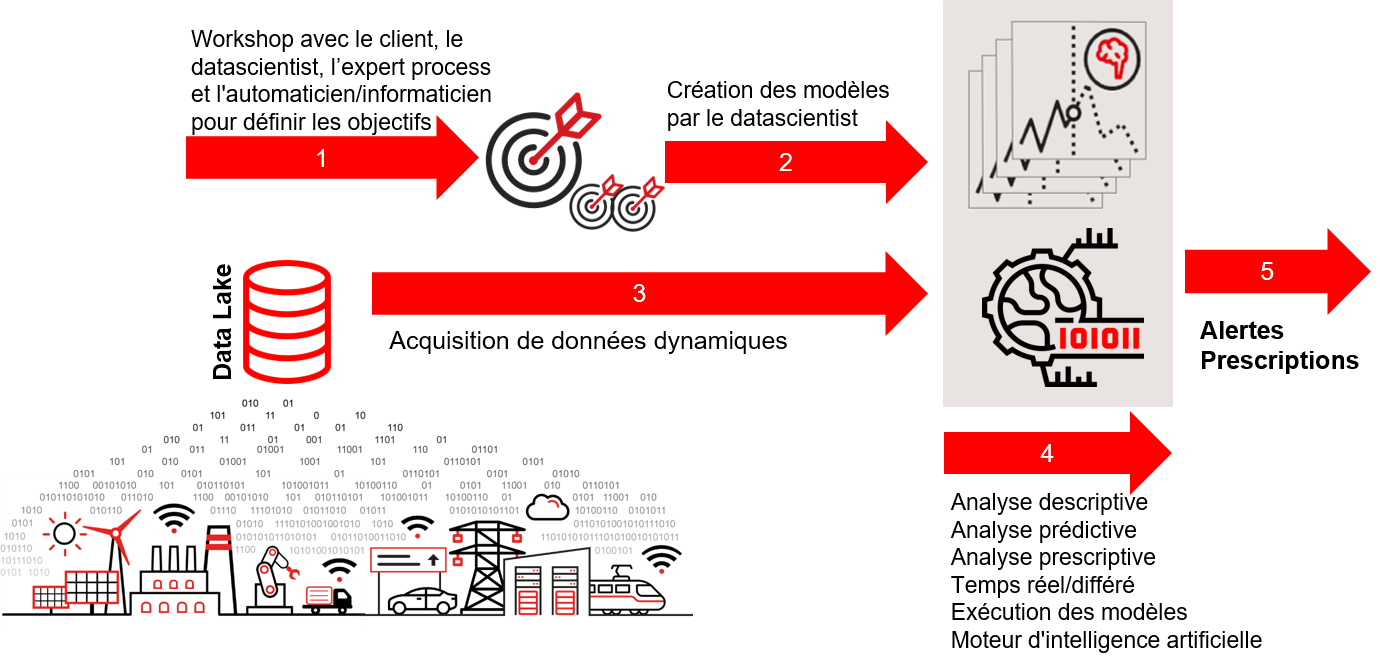

To enable all industries to become more and more efficient, we have developed a Data Science platform called SmartForest. It works with Big Data combined with an Artificial Intelligence engine. The platform collects, aggregates and exploits data more thoroughly than traditional systems, thereby paving the way for predictive and prescriptive analyses. The algorithms are designed on the basis of your challenges and needs to provide:

- Reports based on advanced KPIs (descriptive analysis)

- Detection of deviations from a reference behaviour (predictive analysis)

- Proposals for remedial action based on feedback (prescriptive analysis)

What is Data Science?

Performance: the permanent challenge faced by industry

Complementing the existing environment, our solution accelerates your digital transformation. It consists of a robust software platform thanks to which we can offer a comprehensive Data Science service based on predictive and prescriptive analysis. With SmartForest, you can:

- Improve your industrial performance: discovery of performance issues, notification of boundary conditions of use, reduction of downtime

- Contribute to the improvement of the quality of your products by specifying more optimal production settings and by estimating the wear of a component without stopping the process

- Increase the availability and service life of your equipment: predictive and prescriptive maintenance

- Help your operators with their tasks and mobility: reduction of process times

- Facilitate operations by controlling energy efficiencies

- Be responsive to the market

SmartForest goes beyond traditional systems (MES, SCADA, supervision) to:

- Aggregate data from several sources (process, sensors, settings/revenue, etc.) to extract new knowledge

- Analyse the interaction between tens and hundreds of variables

- Detect complex patterns that cannot be captured in 2D or 3D displays

- Use predictive models in cases where the relationships between variables are not linear or simple

- Analyse big data that requires considerable computing power

- Deal with noisy or unreliable data

- Extract knowledge from non-traditional data (e.g. text, images, video, etc.)

- Develop sophisticated pipelines that can act on data streams in real time (ingestion, pre-processing, descriptor extraction, forecasts)

From preventive maintenance to predictive and prescriptive maintenance

Predictive maintenance means intervening at the “right time”, neither too early nor too late. The aim is to understand or even anticipate a problem thanks to data, to diagnose it and finally to sound the alarm before the incident occurs, thanks to the SmartForest Data Science platform.

Prescriptive maintenance means prescribing corrective maintenance actions associated with a probability, derived from the history and the context. It provides advice on the cause of the fault, helps the technician while he or she carries out the work and optimises the cost of corrective maintenance.

Thanks to this turnkey solution - from the installation of the sensor to the creation of a mathematical model, including data acquisition, analysis and mass storage - you will be able to:

- Understand what is happening

- Find the influencing factors of a cycle-time variation

- Identify the origin of a malfunction / Detect any deviation from a reference behaviour

- Predict the time a fault shall occur

- Increase the accuracy of preventive maintenance

- Prescribe maintenance actions / Put forward remedial actions based on feedback

- Intervene effectively at the right time

Advanced diagnosis of industrial installations

Find the factors responsible for a complex element in a process (cycle-time variation, irregular quality, etc.) or the origin of a malfunction thanks to the SmartForest Data Science platform.

Our solution is used on an ad hoc basis, in production or maintenance, to address problems with a high economic impact. SmartForest generates new data from the modelling of complex elements within a process, which paves the way for even more detailed analyses. It therefore improves industrial reliability.

SmartForest provides a data ingestion and storage service, and a service for the automation of these models to:

- Characterise the factors affecting the productivity of a machine

- Define optimal settings

- Manage the performance and predictive maintenance of a piece of equipment

Intelligent installation-management assistance

To detect any deviation from nominal operations, due to component wear or boundary conditions of use, and to obtain instructions on optimal production settings thanks to the SmartForest Data Science platform. Our solution will reduce your downtime and homogenise the quality of your products.

Intelligent operational assistance

Analyse large volumes of industrial and technical data thanks to the SmartForest Data Science platform to find recurrent patterns and correlations.

This operational support tool is available in real or delayed time, and works with existing systems. In particular, it allows you to:

- Forecast production on the basis of a predictive mathematical model that automatically adapts to changes to the equipment (natural deterioration, fouling, breakdowns, etc.)

- Monitor and predict the life cycle of components

- Optimise data analysis to draw up draft maintenance plans

- Facilitate the search for the cause of a malfunction thanks to data cross-referencing

- Find connections between equipment

- Diagnose the causes of problems in an automated manner while taking variables into account

-

Manage and control production

-

Manufacturing execution/MES

-

Test systems

-

Cybersecurity: secure industrial systems

Consult all our job offers

Available to apprentices, to people looking for an internship or a job, and also to Eiffage employees, the Taléo search engine is the best way of finding out about openings available within the Group. “Area of employment”, “Location”, “Organisation”, “Fixed-term contract”, “Open-ended contract”, “Internship”, “Apprenticeship”: just fill in a few criteria to have real-time access to all the professional development opportunities.